Our Resources Recovery business segment (previously known as Commodities) offers waste management solutions, treatment, recovery, and recycling of industrial waste, electronic waste, and lithium-ion batteries for the EV industry.

Based in Singapore with an established track record of more than 25 years, the Group’s wholly-owned subsidiary, SMC Industrial Pte Ltd (“SMCI”), is committed to providing recovery and recycling solutions and services to our customers to address increasing concerns about waste generation, in particular, electronic and lithium-ion battery waste.

We are committed to the recycling and reintegration of waste into the supply chain by consistently enhancing our process and technology to make recycling both convenient and affordable.

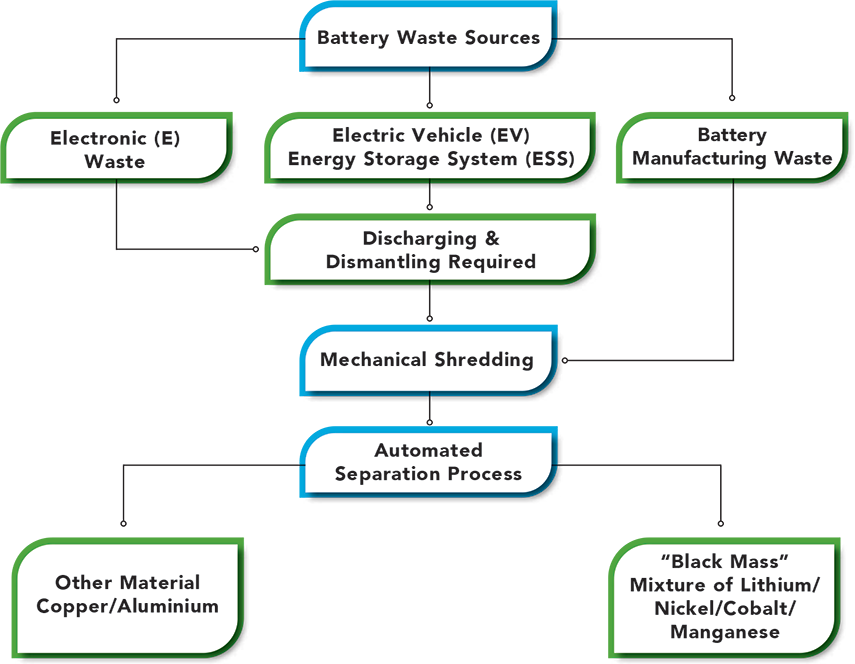

One of our key electronic waste (“e-waste”) management services is ‘battery recycling’, where the recycling process typically begins with the receipt of one of the following waste sources:

- discarded electrical or electronic equipment such as spent lithium-ion batteries from portable devices;

- battery manufacturing waste generated by manufacturer(s) that made battery for electric vehicles/ energy storage systems; and

- end-of-life battery modules generated from scraped electric vehicles.

Additional steps are required for end-of-life batteries at recycling facilities, where they undergo testing, discharging, and disassembly.

Next, the waste batteries undergo a shredding process, which is followed by the separation of the active material of the electrode and current collector foil. This process yields a variety of material fractions, including ‘black mass’, which is in a powder that contains valuable materials such as nickel, cobalt, lithium, and graphite.

Currently, this ‘black mass’ is used as a feedstock by our downstream customers for two processing purposes: (i) hydrometallurgical processing, which involves treating the screened ‘black mass’ extensively with acids to dissolve metals, and (ii) pyrometallurgical processing, which involves smelting batteries in a furnace to recover cobalt, nickel, and copper in the form of alloys.

‘Black mass’ is also being used as a feedstock in several ongoing research and development projects for innovative recycling processes, which we anticipate will result in a rise in demand.

The following chart illustrates the general recycling process of battery waste.

We will continue to explore collaborative opportunities through enhancing our competencies to better support our customers with value-adding solutions.

SMCI’s operations and facility are accredited with the following:

- certified with ISO 9001:2015 standards by Lloyd’s Register Quality Assurance (“LRQA”) on the recycling and sales of e-wastes, ferrous and non-ferrous metals

- licenced by the National Environment Agency of Singapore for the establishment and operations of Lithium-ion Battery Recycling Facility

- licenced by the National Environment Agency of Singapore as a Toxic Industrial Waste Collector

- licenced by the National Environment Agency of Singapore as a Class A General Waste Collector

To remain competitive in the recycling industry, the Group added a new battery processing line in FY2024 to enhance its operational efficiency and the recovery capability of lithium-ion batteries.

ACCREDITATIONS

SMCI is certified with ISO 9001:2015 standards by LRQA on the recycling and sales of e-wastes, ferrous and non-ferrous metals.

SMCI is licenced by the National Environment Agency of Singapore for the establishment and operations of Lithium-ion Battery Recycling Facility.

SMCI is licenced by the National Environment Agency of Singapore as a Toxic Industrial Waste Collector.

SMCI is licenced by the National Environment Agency of Singapore as a Class A General Waste Collector.

The Group remains committed to strengthening our core business segments, particularly the Commodities segment as e-waste recycling is one of the significant solutions to address the depletion of natural resources.